Overview

We offer a wide range of loose needle rollers, pins, axles, and shafts in high volume for use in your assembly. Our bulk process ensures that we can provide consistent precision and exceptional value, produced at competitive prices. Our various needle rollers, axles, and pin products are used throughout many automotive applications, plus can be used in medical equipment. Our vast selection of products vary in type and size for specific industrial applications.

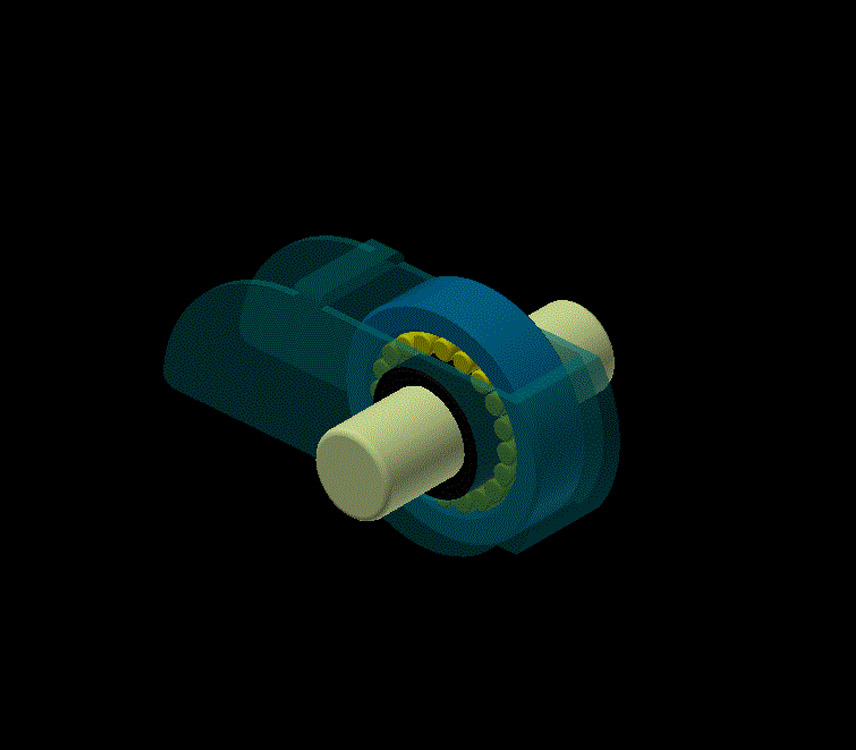

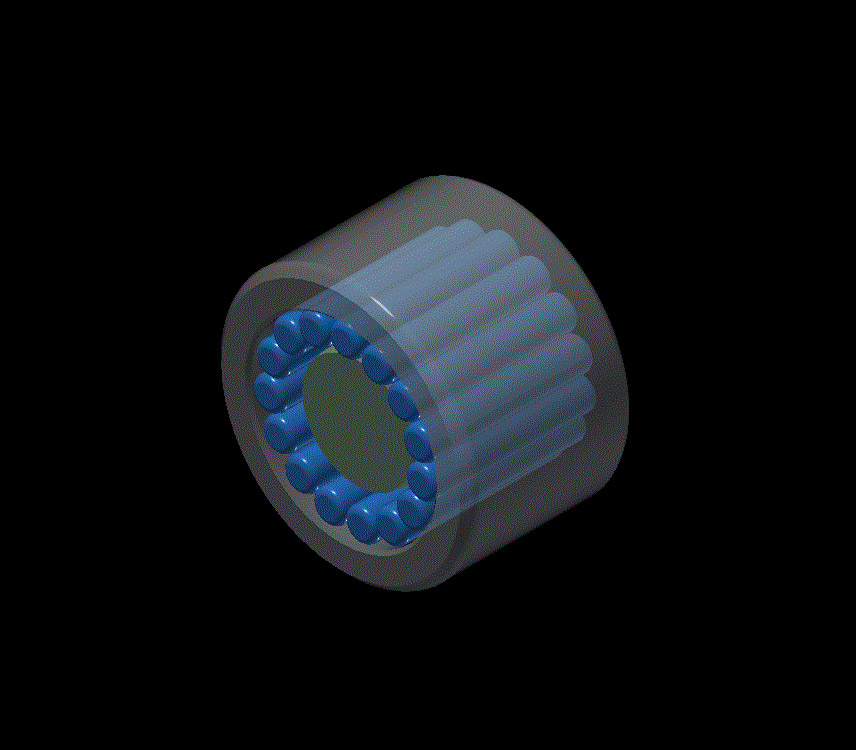

Needle Rollers

Quality precision needle rollers and cylindrical rollers. Our loose needle and cylindrical rollers are used in a wide range of applications. Our extensive engineering experience equips us with the capability to design loose needle or cylindrical rollers based upon your specifications. We’ll work with you to manufacture a product per your exact design.

Specifications

| Dimensions | (1.5 mm – 12mm) x(4mm-100mm) Diameter x Length |

| Materials | SAE 52100, SAE 1085, SAE 1055, Stainless steel 303, 304, 313, 440 |

| Hardness | Standard through-hardened and temper HRC 60-64; custom hardness is available |

| Finishes | Controlled Contour, Ground, Tumble Polished, Super finished or Honed |

| Tolerances | G2, G3, G5 and others on request |

| Machined Features | Radius, Tapers, Grooves and Flats |

| End Profiles | Flat, Spherical |

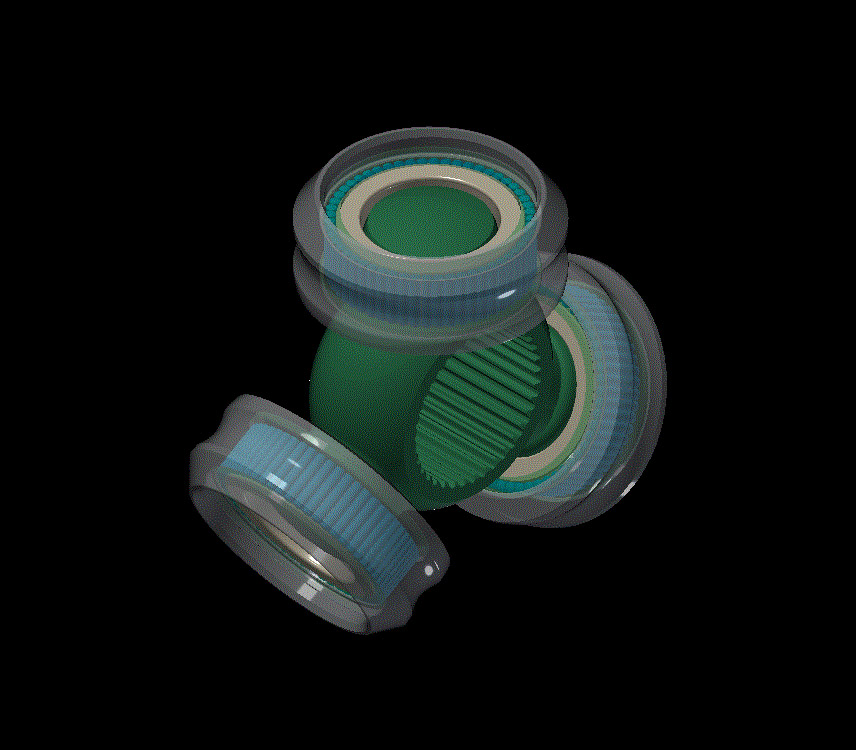

Axles

Our induction-hardened lifter axles are most often used in engines with rocker arms, hydraulic lifters and fuel pumps. Our various lifter axles are precision machined. Properly functioning bearings are improvements in fuel efficiency and bearing longevity. Meeting today’s demanding engine improvements in fuel economy and reliability. By specifying durable products such as axle lifters, you’ll save on costly future repairs.

Specifications

| Dimensions | (4.5mm – 10mm) x (8.5 mm -30 mm) Diameter x Length |

| Materials | SAE 52100, SAE 1085 |

| Hardness | Standard through-hardened and temper HRC 60-64; custom hardness is available |

| Finishes | Ground, Tumble Polished, Super finished or Honed |

| Tolerances | G2, G3, G5, and others on request |

| Machined Features | Drilled ends, cross-drilled holes, clip grooves |

| End Profiles | Flat, Dimpled |

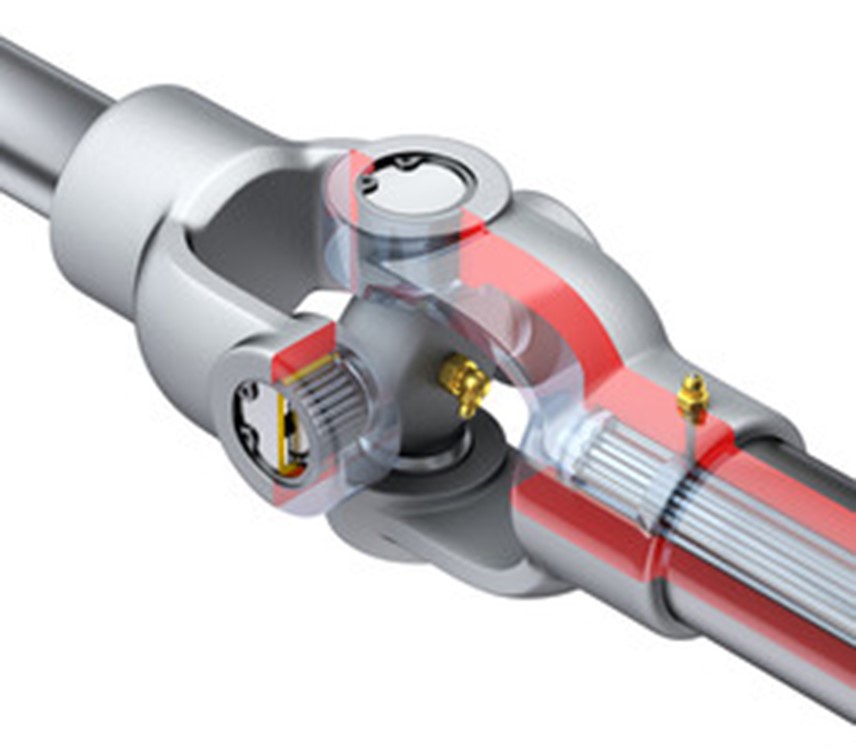

Pins

We produce induction-hardened pinion pins often used in planetary gears and planetary gear shafts found in automated transmission and transfer cases. Our engineering team can help design planetary pinion pin in conjunction with proper design needles to meet your specific needs. Our mass production process for planetary pins makes our pins the choice of top global manufacturers of leading truck and SUV manufacturers.

Specifications

| Dimensions | (4.5mm -20 mm) x (8.5mm – 100mm) Diameter x Length |

| Materials | SAE 52100, SAE 1085 |

| Hardness | Standard through- hardened and temper HRC 60-64; custom hardness is available |

| Finishes | Ground, Tumble Polished, Super finished or Honed |

| Tolerances | G2, G3, G5, and others on request |

| Machined Features | Dimpled Ends, drilled ends, cross-drilled holes, clip grooves |

| End Profiles | Flat, Dimpled |

Dowell Pins, shafts, locating pins

Our dowel pins provide precision alignments and easy insertion. These are essential for places where centerline tolerances and precision alignment are required. Our locating pins are also essential when it comes to aligning two pieces together. We have various shafts to choose from depending on your needs. Browse our selection today.

Specifications

| Dimensions | (1.5mm -12 mm) x(4mm -100mm) Diameter x Length |

| Materials | SAE 52100, SAE 1085, SAE 1055, Stainless steel 303, 304, 313, 440 |

| Hardness | Standard through-hardened and temper HRC 60-64; custom hardness is available |

| Finishes | Ground, Tumble Polished, Super finished or Honed |

| Tolerances | G2, G3, G5 and others on request |

| Machined Features | Radius, Tapers, Grooves and Flat |

| End Profiles | Flat, spherical, contoured |

Needle Rollers, Axles, and Pins

Have any Questions?

Reach out to speak to an expert! Our team will work to answer any questions you have.