Our team at Universal Bearings is ready to help! Check out our FAQ page below for answers to commonly asked questions. If you still need help, don’t hesitate to contact us.

We can manufacture a wide array of needle bearings in different sizes. Please consult this list for more information:

We customize each needle roller bearing based on your unique needs. The materials that we use will vary depending on the type of needle bearing you are requesting:

Currently, Universal Bearings is still being challenged by COVID-related labor shortages, transportation delays, and MRO supply delays. Because of these difficulties, our lead time is 12 weeks. Of course, the lead time will vary depending on the scope of the job. High-volume orders will take more time. We also keep an archive of bearing designs—if you use one of our designs, that may reduce the lead time. If reverse engineering is required for your custom order, that will also add onto the lead time.

When you place a purchase order with us, a team representative will provide you with a more accurate estimate.

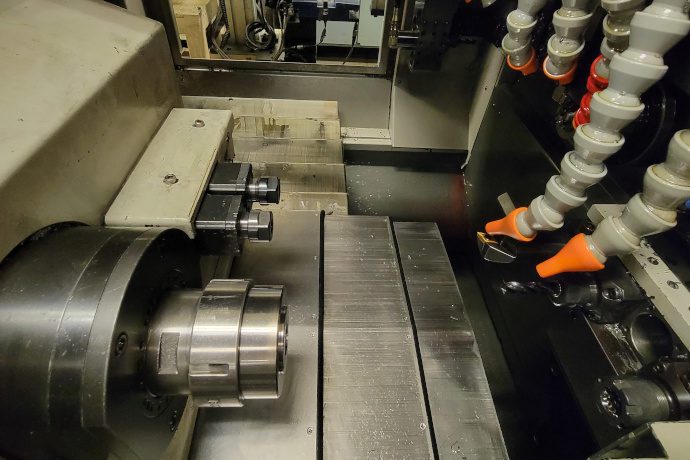

Universal Bearings uses high-quality CNC lathes and grinders to create precision shafts and pins up to 35 millimeters in diameter, as well as needle bearing rings and races for rocker arms, hydraulic lifters, and more. If you have a design in mind, please contact us today, and we’ll let you know how we can help you.

No. Universal Bearings is not a supplier, we are a manufacturer of custom needle roller bearings and bearing assemblies. We do keep a supply of loose needle rollers, but we do not supply bearing assemblies from other manufacturers.

We ship anywhere in the United States. Please note that shipping fees may vary based on the state we are shipping to.

No. Universal Bearings only manufactures custom needle roller bearings and needle bearing assemblies. Additionally, we do not manufacture tapered rolling elements. You can view our complete list of custom bearing assemblies here.