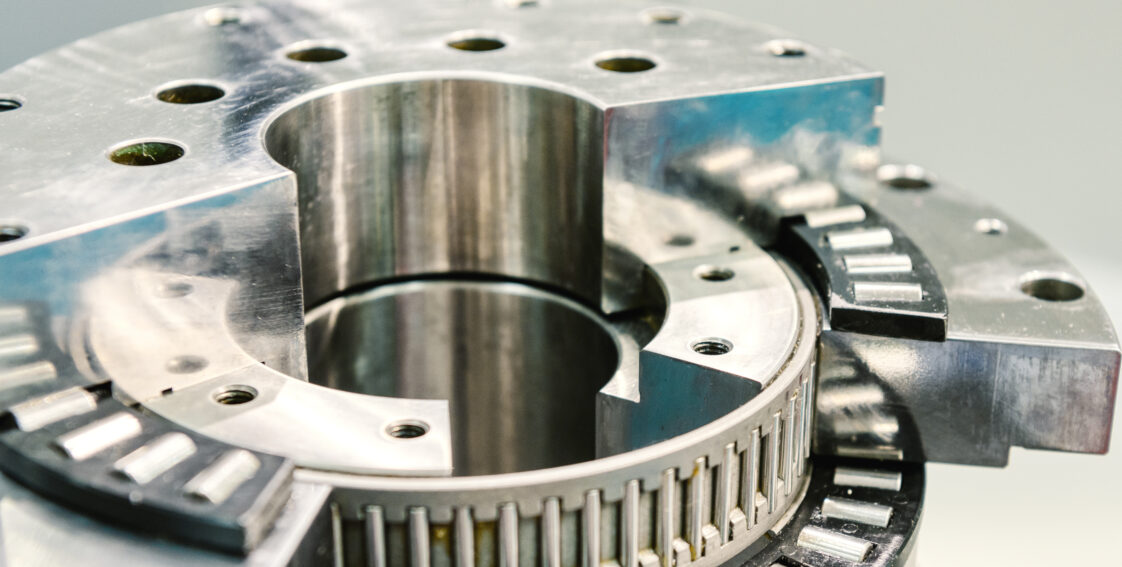

Needle Roller Bearings: Advantages Explained

Needle roller bearings are durable, compact, and lightweight and are typically preferred over ball bearings when space is limited. They have rollers resembling needles, and their length generally is four times longer than the bearing’s diameter. Additionally, like all bearings, the primary function of a needle bearing is to reduce friction between moving parts.

You can read our Guide to Needle Bearings to learn more about the various types of needle bearings and their applications, or continue reading below to learn more about some of the unique advantages of needle roller bearings.

Advantage #1: Low Maintenance

Most needle roller bearings don’t require daily, weekly, or even monthly maintenance. However, they do need to be kept adequately lubricated. This means choosing the right type of lubricant and ensuring that the proper amount of lubricant covers the rolling elements (needles) of the bearing.

Proper lubrication is also essential to keeping dirt and debris out and protecting the bearing against corrosion. Equally important is knowing when to lubricate and how much lubricant to use. The best solution often involves installing an automatic lubrication system so that the bearing receives the correct amount of lubricant at the right time.

Our How to Maintain Your Needle Bearings guide offers more insight into selecting the proper lubricant and other maintenance recommendations.

Advantage #2: Exceptional Axial & Radial Load Capacity

Industrial needle bearings can also withstand high axial and radial loads. This differentiates them from ball bearings, which are typically reserved for applications where high axial and radial load requirements aren’t as necessary.

Axial loads, sometimes referred to as thrust loads, are forces exerted parallel to the axis, while radial loads run perpendicular to the axis. Needle roller bearings have excellent axial and radial load capacity because they support high loads on the mounting surface (axial direction) and radial direction.

Advantage #3: Excellent Rigidity

Rigidity refers to a material’s ability to maintain its shape and not deform, bend, or break when a high external force is applied. Industrial needle roller bearings have excellent rigidity, and even a small amount of elastic deformation on a needle roller bearing won’t typically affect its operation. Using rigid bearings in tight-fitting applications with high axial and radial loads helps to protect mating surfaces and adjacent parts from friction and excessive wear.

The rigidity will vary based on the bearing’s size and the type of needle roller bearing used. Factors including the physical space the bearing must occupy, alongside the amount of axial and radial loads the bearing must withstand, should always be considered. Increasing the number of rollers used will increase the rigidity.

Advantage #4: Great for High-Speed Applications

Ball bearings generate lower amounts of centrifugal force during high-speed applications. This increases friction, leading to the ball bearing overheating and eventually breaking. Comparatively, needle roller bearings generate a higher centrifugal force with high rotational speeds because the needles are longer and weigh more than the balls in ball bearings. Needle roller bearings also generate high rotation and won’t overheat at high speeds, which makes them ideal for high-temperature applications.

Advantage #5: Low Coefficient of Friction

Friction occurs when a given material or surface encounters resistance when sliding, moving, or rubbing against another. The coefficient of friction refers to the ratio of friction between the two materials relative to the normal force that would otherwise keep them together.

A low coefficient of friction means that the resistance between the two surfaces is low. Needle roller bearings have a low coefficient of friction during operation. This means that friction is low, and as a result, the bearings won’t overheat. It also means the bearings don’t require much lubrication to control friction between mating surfaces.

Advantage #6: Exceptional Mechanical Properties

Lastly, mechanical properties vary based on the material the bearing is made of. However, for the most part, manufacturers will heat treat a needle bearing to improve its mechanical properties. Heat treatments can increase a bearing’s strength, durability, hardness, ductility, elasticity, and wear resistance.

Since the bearing will be in contact with other metals, increasing its hardness, tensile strength, ductility, and wear resistance through heat treatment helps to extend the life of the bearing while protecting any mating surfaces. This leads to a stronger, more durable bearing that lasts longer and requires fewer replacements.

Learn More About Our Needle Roller Bearings

There are multiple variations of needle bearings. Criteria such as operating temperature, physical space, and axial and radial loads should always be considered when choosing a standard bearing or designing a custom one.

If you have questions about needle roller bearings or need help selecting the best one for your application, reach out to Universal Bearings. Founded over six decades ago, we’re an ISO 9001- and IATF 16949-certified manufacturer specializing in radial roller cage, drawn cup, thrust, and custom needle roller bearings. We’re also one of the only independent loose needle roller supplies in the world. We offer a wide range of design and manufacturing capabilities, including induction hardening, carbonitriding, and ferritic nitro-carburizing. Please contact us today to learn more about our capabilities and bearing designs or to request a quote.